Louisa’s Blog

September 26, 2012

The Year is 1974:

We are going to laterally move the largest and

heaviest building in the world in 10 days instead of 10 hours.

Day 1

©Antonio Paez Restrepo. All rights reserved.

This aerial photograph shows clearly the obstacle that the CUDECOM building, created for the proposed extension of the important and central Avenue 19 towards the west in Bogota, Colombia.

(Weight 7,000 Metric Tons, Distance 95 Feet)

Day 2

We have a lot to accomplish today. 4 smaller neighboring buildings

need to be demolished including their foundations, to create the

space for the future home of Cudecom.

©Antonio Paez Restrepo. All rights reserved.

It was necessary to acquire four smaller neighboring buildings to create the area where the Cudecom would be moved to.

Shown are two of them.

©Antonio Paez Restrepo. All rights reserved.

This is the start of their demolition. It also shows the direction the Cudecom building will go during its displacement.

©Antonio Paez Restrepo. All rights reserved.

The general dimensions of Cudecom were: 82 Ft wide and 164 Ft Long (along Avenue 19). The original weight was 7000 Metric Tons (15,400,000 Lbs), which increased to 8000 MT (17,600,000 Lbs) at the time of the move because of the addition of beams that strengthened the base and traveled with the building.

Day 3

Today we are initiating the work under the Cudecom building itself. We will be excavating down from the original ground floor to the foundations and beams of the original structure. We are also constructing new beams to serve as rails during the displacement; they bridge between the old foundations and reinforce it. This will provide additional bearing area for Cudecom during the move.

©Antonio Paez Restrepo. All rights reserved.

The foundation consisted of square concrete footings resting on firm Clay, about six feet below grade. All the columns were joined by strong concrete beams, creating strength at the base of the original structure. This was called ‘The Stationary Structure’.

©Antonio Paez Restrepo. All rights reserved.

To create support for Cudecom as it moved to its new location, new footings were built between the old foundations and a ‘Bridge Beam’ joining them to distribute the load and also become the ‘Rail’ for the building’s forward movement.

©Antonio Paez Restrepo. All rights reserved.

The ‘Rail Beam’ is complete between columns, embracing them. It leaves a space below the original Foundation beams of Cudecom.

©Antonio Paez Restrepo. All rights reserved.

Over the ‘Rail Beam’ a metallic element is placed (welded), over which the Rollers will move; some can be seen on each side of the columns, plastic-protected for now.

Day 4

We have finished the ‘Stationary Structure’ (Beams and Rails) under the Cudecom building and along its route. Time to place the Steel Rollers (assembled in carriages of 5) over the rails, to the side of each column (The number of rollers is proportional to the column loads). We also need to work feverishly on constructing the ‘Rail/Foundations’

along the path Cudecom will travel on.

©Antonio Paez Restrepo. All rights reserved.

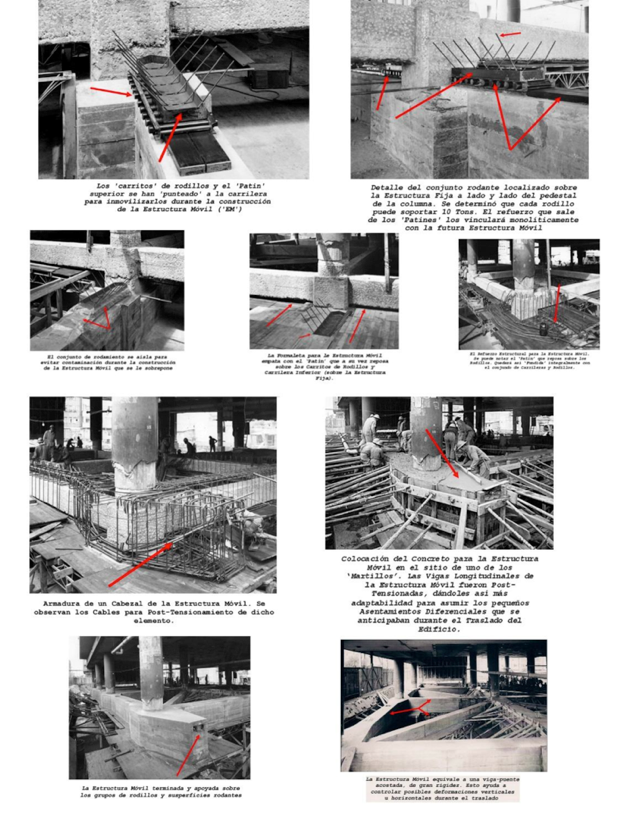

The steel Rollers are 2 Inches in diameter. They were arranged in separate ‘Carriages’ for ease of handling and their width corresponds closely to that of the steel rails placed over the ‘Fixed Structures’ concrete beams.

©Antonio Paez Restrepo. All rights reserved.

This shows the typical location of rollers and carriages over the steel rails. They are arranged to either side of the columns.

©Antonio Paez Restrepo. All rights reserved.

The Rollers are in position to each side of an interior column. There is space between them and the original Tie-Beam of the Cudecom building. The next image explains why the space was left.

©Antonio Paez Restrepo. All rights reserved.

The steel Rollers have to be ‘sandwiched’ between two metallic surfaces. You can also see now the upper metallic element on top of the steel cylinders.

©Antonio Paez Restrepo. All rights reserved.

This shows a corner column and the concrete Foundation Beams built to support the Cudecom building as it travels West to its final destination. The Roller ‘Sandwiches’ can be seen on either side. Note that all the column loads of the original building still are still transmitted to their original foundations. The safety of the building has not been compromised.

©Antonio Paez Restrepo. All rights reserved.

This panoramic view shows how big the Cudecom building and project really is. The 8 Rails (highlighted with red arrows) correspond to the column lines. The building will travel over them, leaving behind its old foundations.

Day 5

Rule number one of delicate work performed on buildings is: "From the moment you start, till you finish, the building should be in better shape than at the beginning." That is why we first relieved the load on the Soil (excavating to reach the original foundations); then we reinforced the Foundations by constructing the very solid 'Fixed Structure' which ties the column bases together. Then we put steel rails over them, Roller Carriages, and an upper steel surface to create a very well confined "Roller Sandwich". Today we are building a network of beams over those 'Sandwiches' and between the columns, creating such a strong bond between the columns at their base that the whole combination will move as one when pushed by hydraulic jacks to its new location. The building says he has felt much better since we started..

©Antonio Paez Restrepo. All rights reserved.

We built the beams over the "Roller Sandwiches" taking advantage of the original foundation beams of Cudecom by encasing them into the new pre-stressed concrete beams of the 'Moving Structure'. We called it so because it will move with the building during the displacement, and stay with it for life. It is designed to eliminate distortions during the move, vertical or horizontal. It is, in comparison, like a very strong 'Chassis' under a Locomotive! The pushing force of the Hydraulic jacks will be applied to one end of this 'Moving Structure'.

Day 6

Today we have a critical day ahead. It could be called “The Proof is in the Pudding”, because we are testing ‘Full Scale’ the work done before, by cutting the columns of CUDECOM and transferring their loads to the ‘Roller Sandwiches’ placed to the side of each column. A typical column is attached to the ‘Moving Structure’, which in turn bridges the demolished column segment and transmits the load to the rollers, and through them to the ‘Stationary Structure’ under them and finally back to the original foundations of the building. We used small Dynamite charges to speed the process since there are many columns. The building hardly noticed it.

©Antonio Paez Restrepo. All rights reserved.

The volume left by the segment of demolished columns is replaced by additional ‘Roller Sandwiches’ matching exactly with the similar elements placed before, next to them. We have then placed the entire Cudecom building over rollers and rails under each column, and one could say that “we are ready to roll”. The Deflection Gauges at each location indicated ZERO vertical movement of the structure during the whole process. On Day Seven we will describe the mechanical installations, hydraulic ‘Jacks’, pumps, and other monitoring equipment etc.

Please continue on next blog page to see Day 7

Copyright Antonio Paez Restrepo

©Antonio Paez Restrepo

© Antonio Paez Restrepo

©Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo

© Antonio Paez Restrepo